India: Involute , a long-standing leader in powder metallurgy innovation, has unveiled a breakthrough suite of proprietary technologies aimed at solving one of India’s most urgent industrial and environmental challenges—the large-scale accumulation of iron ore tailings .

With more than one billion tons of tailings currently lying unused across the country, Involute’s solutions promise to convert this underutilized waste into high-value industrial materials.

Since iron ore is primarily used for iron and steel production, the following categories of processed ore materials are classified as tailings :

Specifically Iron ore tailings are fine particles left after ore processing—occupy thousands of hectares across mining belts in India and pose significant environmental hazards due to their silica-, alumina-, and trace-element content. Traditionally considered a waste burden, these tailings now represent a major opportunity for value creation through Involute’s process-driven innovations.

INVOLUTE’s solutions are not only designed to address a critical national challenge, but they also create a strong impetus for deploying multiple Involute process technologies. These technologies enable significant value addition to otherwise classified “wastes,” while simultaneously facilitating the reclamation of vast tracts of land for vegetation, green cover, and other productive infrastructure developments.

Involute’s Breakthrough: Turning Tailings into High-Value Powders

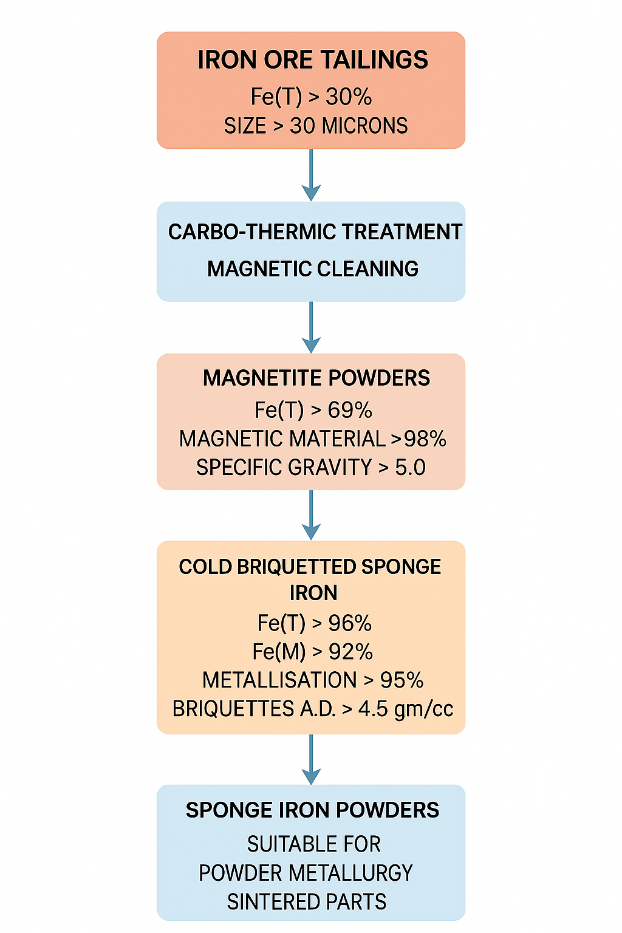

Through decades of research, field trials, and the integration of previously held patents, Involute has developed advanced technologies including double-stage reduction , DRI-based processing , and specialized powder metallurgy routes .

From tailings that cost roughly ₹500–1,500/tonne , it is possible to produce High worth Sponge-iron powders with a market value of ₹75,000–90,000/tonne . These processes convert low-grade ores, ultra-fines, and dusts (below 50 microns) into:

This innovation has the potential to reduce India’s reliance on powder imports from China, Spain, and the US by up to 45%, directly strengthening India’s Atmanirbhar Bharat and Make in India ambitions.

A National Impact Across Core Industries

The high-value powders produced from tailings support critical sectors such as:

By integrating waste back into the production cycle, Involute brings a major boost to India’s manufacturing competitiveness while offering a sustainable, circular-economy model.

Environmental & Economic Transformation

Involute’s technology ecosystem not only converts waste to wealth but also:

The solution represents a convergence of industrial innovation , environmental stewardship , and economic value creation .

A Strategic Call for Industry & Policy Collaboration

Head of Involute Metal Powders, Ms.Soumya Vilekar, shared, “Involute emphasizes that wider adoption of tailings-to-powder technologies—supported by policy incentives, reduced raw material taxes, and manufacturing subsidies—could reshape India’s industrial landscape. With coordinated support, India can emerge as one of the world’s largest producers of iron-based and alloy powders” .With over four decades of expertise in powder metallurgy and material sciences, Involute continues to drive innovation in the utilization of waste materials, advanced reduction processes, and industrial sustainability. The company remains committed to building technologies that align economic growth with environmental responsibility.

Quick Share

The sacred occasion of Shahi Snan on Mauni Amavasya at the Magh Mela in Prayagraj witnessed an overwhelming display of faith, devotion, and Sanatani tradition. The hashtag #SanataniMaghMela stormed...

Mumbai, India — In a space where startups often compete for valuation and dilution, Albon Cosmetics made a bold, conversation-starting move on Bharat Ke Super Founders, now streaming on Amazon MX...

New Delhi, January 2026 — India’s fastest-growing café franchise, TeaMax, has wrapped up 2025 with remarkable milestones, a bold expansion strategy, and renewed purpose heading into the new year....